Waste today – source of raw materials tomorrow

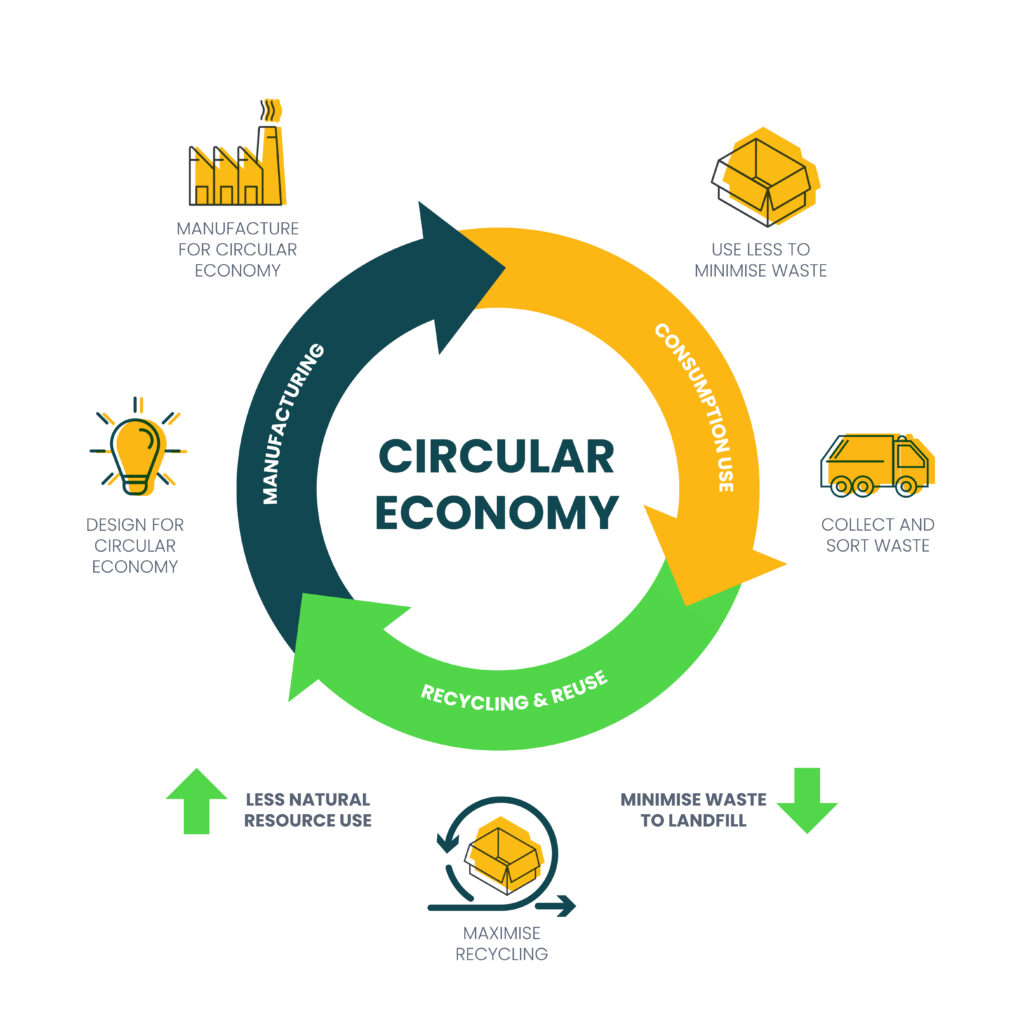

When the alchemists were tasked with turning dirt into gold, they invented porcelain. In the same way, even today, we can make something valuable out of things that are seemingly worthless – for example, from process wastewater, laboratory waste, electronic scrap. Waste could even become the no. 1 source of raw materials for chemicals, pharmaceuticals and biotech.

For example, phosphorus can be recovered from wastewater from the chemical and food industries. Using patented technology, this can even be done without added salts and alkalis, as is usual with classic processes: A magnesium electrode can be used to obtain phosphorus and nitrogen as struvite (magnesium ammonium phosphate) or potassium struvite. Since the struvite is free of biomass, it can be used directly in agriculture as a high-quality fertiliser – and what’s more, it even has the desired “retardant effect”: The nutrients are released slowly and gradually. All this not only benefits the environment, but also has tangible financial advantages. This approach eliminates the need to store chemicals, the whole process is easy to handle, and the struvite can be sold at a profit – a prime example of waste valorisation.

The recycling of gold, platinum and palladium from waste water or from the sludge of sewage treatment plants seems to be economically viable, particularly in Jura and Ticino. This is because the concentrations sometimes reach the level of profitable ore, which is probably due to local precious metal refining and the watch and jewellery industry. The total value of all precious metals in the wastewater streams of Switzerland is in the range of CHF 5,000,000 annually.

Physical, chemical and biological processes can be used for the recovery process. They include, among others, adsorption (especially: biosorption), coagulation/flocculation, electrochemical processes and membrane technologies. Bioleaching is an innovative process: Microorganisms continuously regenerate the leaching agent used to extract the desired metal from the wastewater.

The Ilmac industry event held in Basel, which takes place over three days, offers everything related to “Chemical Technologies” on the second day of the conference. Speakers from renowned companies, such as F. Hoffmann-La Roche AG and Syngenta, will hold lectures on this topic. An attractive conference programme will be organised in collaboration with the Swiss Chemical Society.