» Automation and robotization

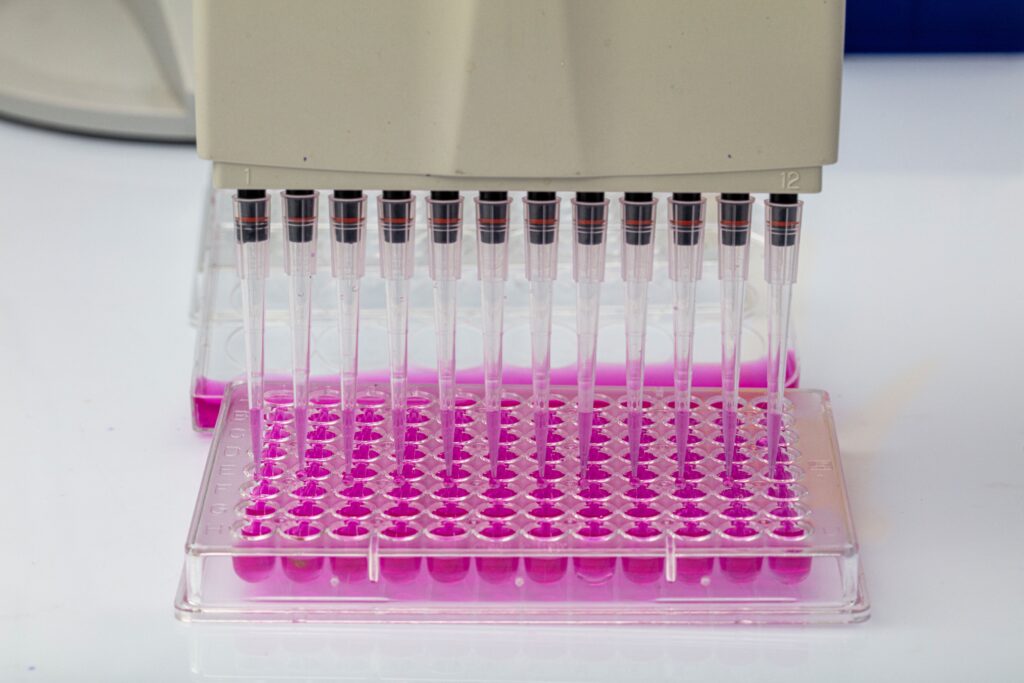

Automation increases the precision, accuracy and efficiency of experiments in research and processes in laboratories, technical centers and production. At the same time, robots can take over the tasks of skilled workers who are in short supply everywhere. Visitors to Ilmac 2025 Basel, the pioneering industry event in chemistry and life sciences, will be able to find out in the exhibition halls what opportunities this opens up for their own company.

In just over 70 years, the path has led from automated individual devices (e.g. laboratory centrifuges) to robots for high-throughput processes and the integration of production control stations and laboratory information systems (LIMS) to today’s synergies with artificial intelligence. And just as LIMS has networked many devices, cloud computing is now networking many laboratories and entire sites worldwide. Process automation in production, including process analytics, has always been a few steps ahead of laboratory automation. But the laboratory is now following suit! The new LADS laboratory equipment standard for efficient networking of devices, automated systems and processes has been a milestone for a good year now. It could be a decisive advantage for local suppliers in the highly competitive laboratory market – and ultimately also an advantage for pharmaceutical and chemical companies, as they have short distances to the systems of domestic laboratory equipment suppliers.

With such extensive automation and robotization, employees’ work will shift from the workbench or production hall to the computer. This applies in general: instead of plugging, screwing and wiring, laboratory technicians will in future establish the connections between reaction vessels, fermenters, chromatographs and much more at the click of a mouse.

In addition to many individual innovations, the main question, as in the example above, is: Which processes and devices can be ideally brought together for a specific task?

Thermogravimetry (TGA) and Fourier transform infrared spectroscopy have already grown together. TGA and differential scanning calorimetry (DSC) also work well in tandem and can then weigh, heat and carry out a calorimetric measurement in one go, optionally with a downstream mass spectrometer (MS). The TGA-DSC-MS provides both heat flow changes and the identity of the substance in one go.

Ilmac Basel 2025 will also feature numerous other application examples and detailed innovations for laboratories and production – each of them an opportunity for your own business. All information about the event, the exhibiting companies and the program items can be found on Ilmac 365, the Ilmac community network: https://365.ilmac.ch/event/ilmac-basel-2025